Facility

Algonac Marine Cast prides itself with a vertically integrated facility that spans 55,000 square feet with total in house capabilities from Design to Cad to Foundry to Machining to Inspection to Shipping, all under one roof.

Algonac Marine Cast prides itself with a vertically integrated facility that spans 55,000 square feet with total in house capabilities from Design to Cad to Foundry to Machining to Inspection to Shipping, all under one roof.

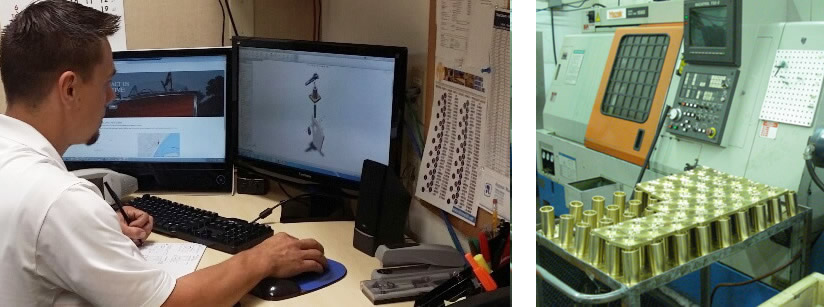

Design and CAD…. we possess state of the art Computer systems and utilize Solidworks 3D/CAD modeling, rapid prototype machines, and our in-house documentation system that provides instant access to drawings for all the part we have ever built…

Having our Pattern Shop on premise, gives us instant access to all our needs, such as building new patterns, on-going repair and maintenance of existing tooling.

Our Foundry is designed and set-up for manufacturing Marine Castings… We cast anything from large bronze struts and rudders, to large cast aluminum parts for ski boat towers… with multiple electric furnaces, automated sand systems to control all the ingredients that make great sand castings from part to part to part.

Our Foundry is designed and set-up for manufacturing Marine Castings… We cast anything from large bronze struts and rudders, to large cast aluminum parts for ski boat towers… with multiple electric furnaces, automated sand systems to control all the ingredients that make great sand castings from part to part to part.

Our in-house machine shop has manufactured top quality parts for some of the most prestigious boat builders for more that 90 years…. it starts with great talented machinist and combined with dedicated machines tooled for specific jobs….

Our shipping/receiving department utilizes best practices for inventory control with all parts assigned to bar codes, drawing documentation and computer generated paperwork to make sure you receive the correct parts every time and on time.